Possibility of packaging different products:

Coffee, soluble tea.

Flavour dosing system:

Option to dose syrups or liquids for flavoured coffee.

Coffee dosage:

Filling up to 6.2 grams per capsule. The screw system activated by a brushless motor maintains a consistency 0.02gram dosage variance from capsule to capsule.

Extraction and cleaning:

Tamp and seal cleaning station for sealing and extraction quality

Nitrogen Flushing:

Inert gas is used throughout the filling process to preserve the coffee’s freshness and aroma, from bean to capsule.

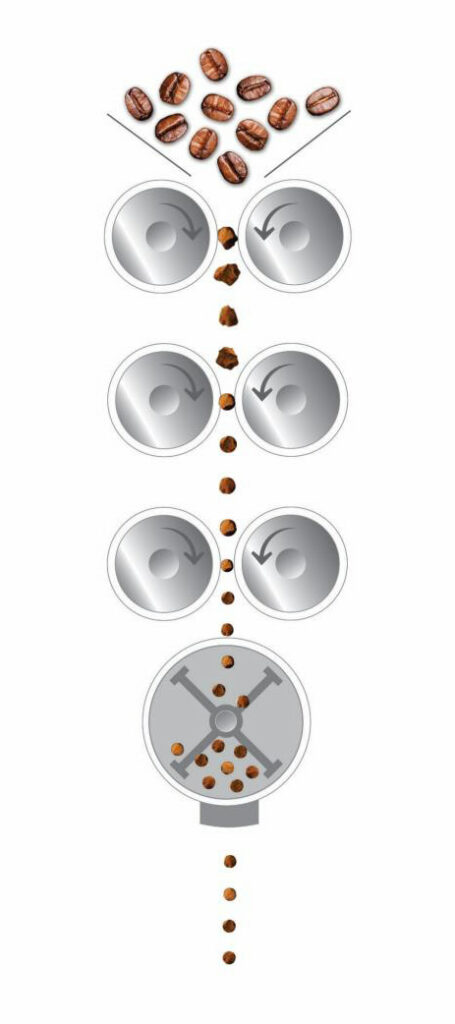

3 stage coffee roll grinder

Water chilled system

Coffee density control

Outcome – Roller grinders output a sharper and more uniform partial distribution profile, allowing a higher solids extraction yield using the same amount of coffee and constant brew times.

The Maipac team will focus on your target market and determine the best way to maximise capsule sales.

Packaging requirements are supplied for your design team – for retail or food service. We can print on the capsule lid and work with you on box and packaging options.

Coffee is nothing if the beans are not right. We work alongside you to determine the appropriate coffee blend (blend or single origin) for you. Then we begin a methodical and measurable sampling process, ensuring your roasted beans are ground within the right cycles, optimising the capsule experience for the end consumer. We believe in the best process before, during and after extraction.

The production process is scheduled, taking into account delivery of beans through to finished capsules. We will work with you to ensure your coffee tastes great and your capsules look their very best. Capsule seals can be personalised with your own artwork and colour matched to your brand. We also provide customised packaging solutions.

An agreement is completed whilst blend sampling and formula is finalised.

Our service includes freight, delivery, and logistics Australia wide. After your capsules have been packed, your freight can be organised and ready for distribution.